Steam volume: 1t / h-25t / h

Steam pressure: 0.7mpa-2.5mpa (optional as required)

Steam temperature: 0 ℃ - 226 ℃

Fuel: coal, anthracite, bituminous coal, lignite, etc.

WhatsApp: +86-17772877223 +86-15090452295

E-mail: info@yuji-boiler.com

Product Introduction

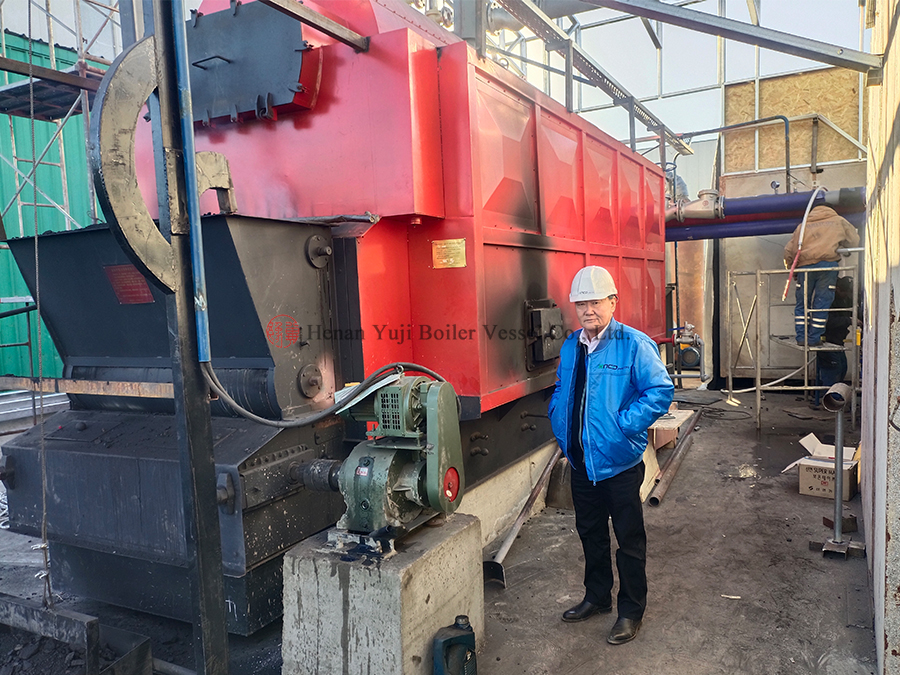

Biomass Fired Chain Grate Steam Boiler is designed as single-drum boilers with fire tubes and water tubes. It has the characteristics of fast heat conduction, quick steam pressure rise, strong adaptability to biomass fuel, compact structure and high thermal efficiency. It adopts new thermal insulation materials, with less heat loss and good thermal insulation performance. It has a built-in limit low water level sensing safety device, which can directly detect the water level in the boiler. This boiler can be your most economical and practical choice.

Features

Biomass Fired Chain Grate Steam Boiler adopts the latest science and technology, such as arched tube plate and threaded flue smoke pipes, which effectively improve the overall efficiency of the boiler and prevent the occurrence of faults including grate coking and tube plate leakage. The combustion chamber furnace arch can be tailor-made according to different shapes of fuel, achieving sufficient combustion and less air pollutants. Its advantages include high steam quality, strong adaptability to load changes, and large steam space volume. This Biomass Fired Chain Grate Steam Boiler also has easy installation and maintenance, able to provide you more reliable and consistent performance.

| DZL Steam Boiler | |||||||

| Model | Rated evaporation(t/h) | Rated pressure(MPa) | Steam temperature(℃) | thermal efficiency (%) | Fuel consumption (kg/h) | Size L×W×H (m) | Weight(t) |

| DZL1-1.0/1.25-AII | 1 | 1.0/1.25 | 193/204 | ≥83 | 176.6 | 5.1×2.2×2.9 | 15 |

| DZL2-1.0/1.25-AII | 2 | 352.3 | 6.14×2.6×3.3 | 18 | |||

| DZL3-1.25/1.6-AII | 3 | 1.25/1.6 | 522 | 6.33×2.7×3.3 | 24 | ||

| DZL4-1.25/1.6-AII | 4 | 571 | 6.88×2.7×3.3 | 27 | |||

| DZL6-1.25/1.6-AII | 6 | 1044 | 7.29×3.2×3.7 | 31 | |||

| DZL8-1.25/1.6-AII | 8 | 1396.5 | 7.8×3.4×3.7 | 33 | |||

| DZL10-1.25/1.6-AII | 10 | 1743.3 | 8.5×3.4×3.7 | 41 | |||

| DZL Hot Water Boiler | |||||||

| Model | Rated power(mw) | Rated pressure(MPa) | thermal efficiency (%) | Fuel consumption (kg/h) | Size L×W×H (m) | Weight(t) | |

| DZL0.7-0.7/95/70 | 0.7 | 0.7/1.0 | ≥83 | 174.3 | 5.1×2.2×2.9 | 15 | |

| DZL1.4-1.0/95/70 | 1.4 | 1 | 348.6 | 6.14×2.6×3.3 | 18 | ||

| DZL2.1-0.7/95/70 | 2.1 | 517 | 6.33×2.7×3.3 | 24 | |||

| DZL2.8-0.7/95/70 | 2.8 | 687.2 | 6.88×2.7×3.3 | 27 | |||

| DZL4.2-0.7/95/70 | 4.2 | 1.0/1.25 | 1024 | 7.29×3.2×3.7 | 31 | ||

| DZL5.6-1.25/95/70 | 5.6 | 1374.3 | 7.8×3.4×3.7 | 33 | |||

| DZL7-1.25/95/70 | 7 | 1708 | 8.5×3.4×3.7 | 39 | |||

Parameters

Model: DZL Series

Steam Capacity: 1T/ H-25T / H

Steam Pressure: 0.7Mpa-2.5Mpa (Optional as required)

Fuel: Sawdust, Biomass Pallet, Rice Husks, Peanut Shells, Palm Shells, Coconut Shells, Corncobs, Bagasse, Bamboo Chips, Straw and Other Solid fuel For Crops.

Application: Chemical factory, sugar factory, pharmaceutical factory, textile factory, printing and dyeing factory, food factory, paper factory, clothing factory, fertilizer factory, feed factory, rubber factory, cement factory, washing factory, hospital, hotel, etc.

Characteristics

1.The design and performance reach the national standard

(1)Boiler design adopts many latest technologies in the industry, with high practical performance

(2)The combustion chamber furnace arch is tailor-made according to different shapes of fuel, so that all kinds of fuel can be fully burned. Convection water pipes are arranged in the furnace arch to maintain the constant temperature of the furnace arch and prolong the life of the furnace arch

2. Special safety design

(1)The boiler drum has a built-in limit low water level sensing safety

device, which can directly detect the water level in the furnace, and no water shortage accident will occur

(2)The boiler body adopts the overall heat treatment process to eliminate steel stress and operate safely

3. High security operation

(1)PLC intelligent control system can realize automatic operation of charging, grate operation, fan start and stop, water supply, slag discharge, etc,it also has interlocking protection functions such as overpressure, overtemperature, water shortage, leakage, motor overload, etc.

(2)Set up multiple safety protections, safety valves, water level alarms, pressure gauges, pressure controllers, etc. to ensure safe operation

4. The design and performance reach the national standard

(1)Boiler design adopts many latest technologies in the industry, with high practical performance

(2)The combustion chamber furnace arch is tailor-made according to different shapes of fuel, so that all kinds of fuel can be fully burned. Convection water pipes are arranged in the furnace arch to maintain the constant temperature of the furnace arch and prolong the life of the furnace arch

(3)Automatic grate lengthening design can prolong fuel burning time and improve thermal efficiency.Using heavy-duty grate design, high temperature resistance, reduced leakage, stable operation and low failure rate

(4)The air supply system adopts two-side air inlet and independent air chamber, which can freely adjust the air volume and air pressure according to the combustion state . Furnace secondary air design fully guarantees the oxygen content, improves the combustion efficiency and makes the fuel not coking

5. Fast assembly and convenient transportation

Boiler and auxiliary machine are assembled structure, the installation period is short, and the lifting and transportation are convenient

1. Material re-inspection: Ensure materials meet standards

2. Pretreatment of materials: Surface derusting and non-destructive testing, plate calibration

3. Cutting process: CNC cutting machine for lofting and processing

1. Forming: The drum is integrally formed. Using corrugated furnace process

2. Welding: Automatic welding, beautiful appearance, low repair rate and high efficiency

3. Correction: The welded drum is rounded to ensure the roundness of the drum

1. Non-destructive testing: Non-destructive testing, mechanical performance testing

2. Hydrostatic test: Check its strength and tightness

3. Trial burning: Safety and Stability Tests

1. Paint: First remove rust, then apply antirust primer, and finally apply high temperature resistant metal paint

2. Packaging: Packaging with special equipment

3. Transportation: Ensure safe and fast transportation of boilers and auxiliary equipment

Please let us know your required steam capacity, working pressure or steam temperature, fuel type. Then our aftersales-engineer will send you the detailed and exact offer.

Usually our company have new stocks, we can manage the shipping within 5-10 days. But you please contact us salesman to confirm in advance.

Yes, our company will provide the drawings and operation manual. Also you can contact us for help, then our engineer can give you the technical supports online.

1. Structure of vertical boiler is compact, occupy a limited area.

2. Convenient on installation and removal.

3. Low cost and investment on capital construction. Steam exhausted fast and sufficient.

4. The combustion space of horizontal is big, fuel can be burned completed.

5. The thermal efficiency is higher than the vertical boiler.

6. Horizontal type: less thermal loss, stronger output, and higher steam quality.

Our boilers have one year warranty period or depending on your requirements.

1. We need to know the boiler capacity, the fuel you plan to use and the steam pressure you need, and then we can confirm the boiler model.

2. Customer needs to provide us your name, email address and company name, and then we will send you price list immediately.And if you use whatsapp, skype or wechat, you can provide us your ID, it will be more convenient for our communication.

1. Strength calculation report with applied materials information.

2. 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod.

3. 100% X-ray inspection( (Longitudinal, transversal safety inspection)): ensure the quality of entire boiler.

4. Hydrostatic test: ensure the standard working pressure and safety.

5. Third-party inspection report:By Henan Boiler Inspection Institute.

6.Passed ISO:9001 ,ISO14001,OHASA18001 and CE certificate.

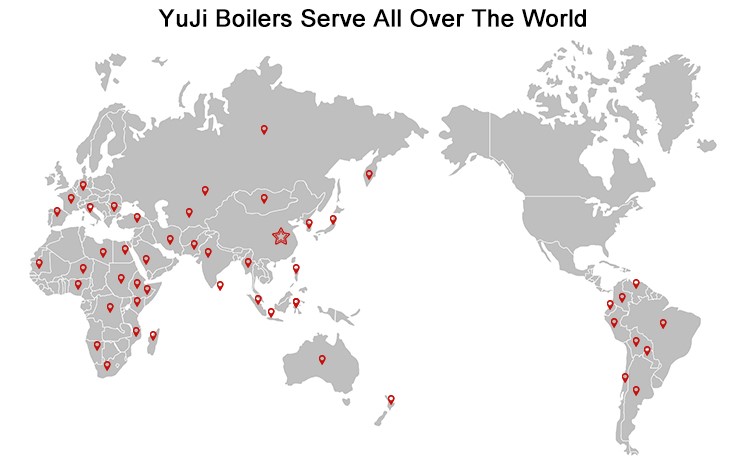

1. We have 20, 000 m² factory area, More than 200 employees. We can efficiently complete your delivery project.

2. Our boiler vessel export to more than 100+ countries, Well Received by Customers.

3. Our boiler vessel have passed the ISO 9001 system certification, EU CE and other international certifications, worthy of your trust.

4. Through the quotation consultation form you submitted, we will give you a quotation and construction solution in the shortest time.

Quote

Business: info@yuji-boiler.com

Technology: clinton@yuji-boiler.com

After sales: admin@yuji-boiler.com

Phone

+86-17772877223

+86-15090452295

The price will be sent soon via email.