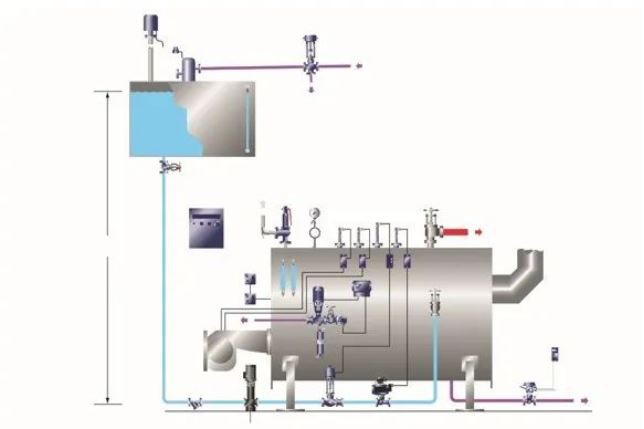

Since the development of the boiler industry, the degree of automation of modern boilers has been very high. Compared with the backward manual control method, a set of steam boilers with complete control systems such as automatic ignition control, pressure control, safety control, liquid level control, and sewage control. Not only can it effectively save manpower and achieve the goal of unattended boiler room, but also it will be safer, more efficient and capable of generating higher quality steam for the boiler. So, today we will talk about the importance of the boiler’s TDS automatic surface blowdown control and automatic level control from the perspective of steam quality and energy saving.

01 What is high quality steam?

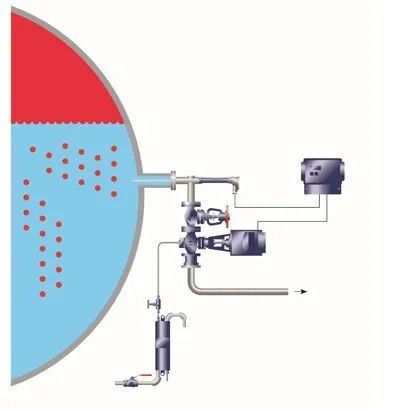

The so-called high-quality steam should not only meet the correct flow, pressure and temperature requirements, but also have the characteristics of being dry, free of moisture, impurities and non-condensable gases. After the boiler feed water enters the boiler, the dissolved solids (TDS) content in the boiler feed water is continuously concentrated as the boiler water evaporates, which not only causes the thickness of the foam layer on the vapor-liquid separation surface inside the boiler to increase, but also causes the boiler water to produce The bubbles are more stable and difficult to rupture. Eventually, steam and water will co-escape and greatly increase the humidity and impurity content of the steam. In severe cases, the steam will also carry a lot of water, causing the boiler to shut down due to low water level. Therefore, we recommend installing a surface continuous blowdown control system for each steam boiler. However, excessive surface blowdown will also cause a waste of energy. At present, the continuous blowdown of many industrial boilers in China is still controlled by manual valves. Control the TDS index of the boiler water, and in most cases will exceed the discharge, increasing the operating cost of the boiler.

02 Boiler continuous surface blowdown control system

If an automatic boiler continuous surface blowdown control (TDS control) system is adopted, not only can the boiler continue to provide higher quality steam, but it can also bring more than 2% fuel cost savings compared with manual control. For example, a boiler with a working pressure of 1.0MPa can save about 0.21% of boiler fuel for every reduction of 1% of the sewage volume, as shown in the following table:

|

Boiler Pressure :Mpa |

For every 1% reduction in emissions, fuel will be saved % |

|

0.7 |

0.19 |

|

1 |

0.21 |

|

1.7 |

0.25 |

|

2.5 |

0.28 |

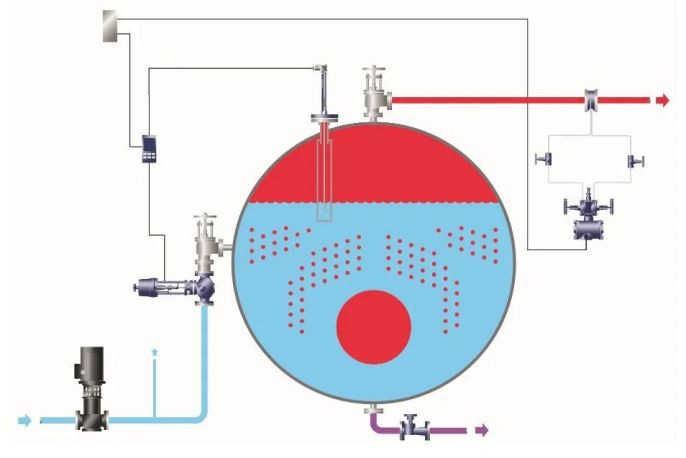

03 Boiler level control system

Compared with automatic surface blowdown control, most modern boilers have realized automatic level control. There are two main control methods: switch control and continuous proportional control. The former is only suitable for boilers with a small evaporation capacity or when the steam load is relatively stable, while the latter control method can not only obtain more stable steam pressure and flow, but also keep the boiler combustion at a higher efficiency and save energy.

In addition, if the steam load changes greatly, the boiler must use a binary feedwater control system. Otherwise, when the boiler pressure suddenly drops due to a sudden increase in load, the volume of bubbles in the water body will rapidly expand, causing a false rise in the boiler liquid level. First, it reduces the area of the steam-water interface, and at the same time, the main steam outlet flow rate is too fast to easily entrain bubbles and salt, resulting in a decline in steam quality; secondly, when the pressure is restored, the boiler water will not be filled in time due to the false liquid level that appeared before , Drops to a very low level and may trigger the boiler’s low water level alarm. Therefore, a good boiler liquid level control system should be able to simultaneously monitor the boiler load, that is, the change of steam flow, so as to ensure the double guarantee of steam quality and boiler operation safety.